Next ACRC Meeting: May 27-28, 2026, OSU, Columbus, OH

Welcome to the Advanced Casting Research Center (ACRC)

ACRC is one of the largest industry-university consortia (~ 40 members) in North America dedicated to collaborative research in metal processing and manufacturing. Our focus is metal casting and digital manufacturing. We bring fundamental understanding to existing processes, develop new methods, new alloys, and address management-technology interface issues with our industrial partners. ACRC serves the global metal processing and foundry industry as its educational and research home.

News Feed

Most-Recent E-Blast

- Collaboration with the Cold Spray and Rapid Deposition Lab at FIU

- Alan Luo Elected to the National Academy of Inventors

- Wulff Lecture at MIT

- ALMEX USA and ACRC Collaboration

- METAL Boot Camp at OSU

- Diran Apelian Upcycles Scrap Metal for Cars and Aerospace

- Meet our Newest Board Members

- Meet our Student Research Team

- Meet our Academic Affiliates

- ESI Group Joins ACRC

- Ohio State Awarded $1 Million for Workforce Development

- Raquel Fierro Jaime Earns AFS Recognition

- AFS Scholarship

- Industry Presenters

PRATT & WHITNEY CENTER OF EXCELLENCE IN SOLIDIFICATION SCIENCE

Pratt & Whitney has established a Center of Excellence for Solidification Science at UCI. Diran Apelian is its inaugural Director, and the team of Andrew Zang, Carl Soderhjelm, Dan Mumm, Julián Rimoli, Kevin Garanger and Lorenzo Valdevit are the core faculty working on the Center’s projects. The Center of Excellence is a hub with ties to OSU, North Carolina State and North Carolina A&T.

ACRC RESEARCH HIGHLIGHTS

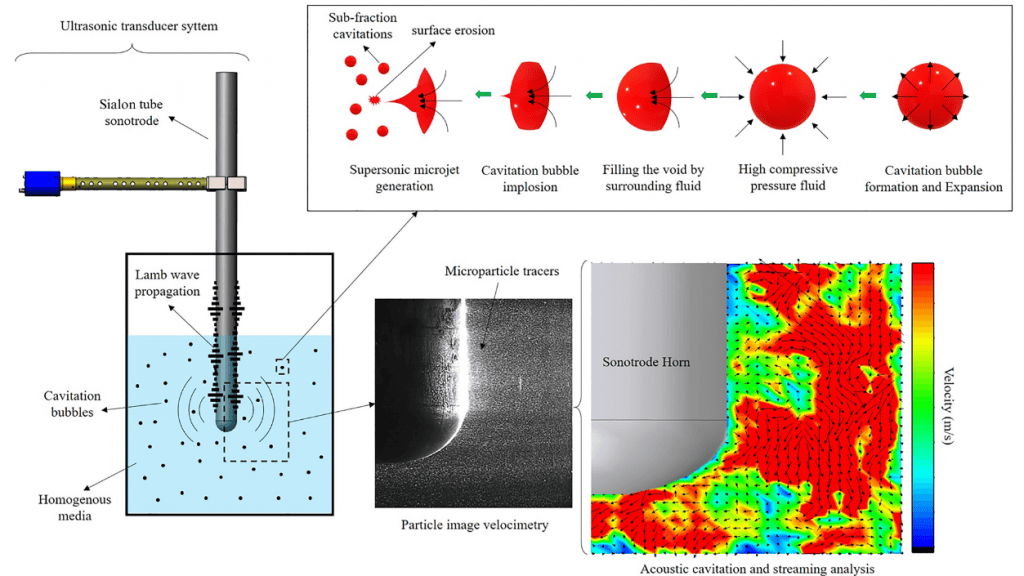

Ultrasonic Processing of Aluminum Alloys

Ultrasonic Treatment (UST) is a novel molten metal processing method that has the potential to perform degassing, grain refinement, and modify intermetallics all in one eco-friendly step. To achieve this goal, the fundamental mechanisms of UST must be researched and developed. The ACRC project on UST is investigating the underlying principles of an innovative multifrequency ultrasonic impartment method and establishing the limiting factors of this processing method in the liquid-state of the metal. Liquid-state UST is a prominent route of exploration to further develop this processing method for many industrial purposes including permanent, gravity casting, sandcasting, launder systems, and high-pressure diecasting. The currently observed benefits of multifrequency UST include the temperatures at which treatment is effective (over 100°C superheat), the volume of metal that can be treated (up to 20 kg compared to 1 kg in traditional fixed frequency), the ability to modify script-like intermetallics into faceted phases, and significant grain refinement (up to 85% reduction in grain size).

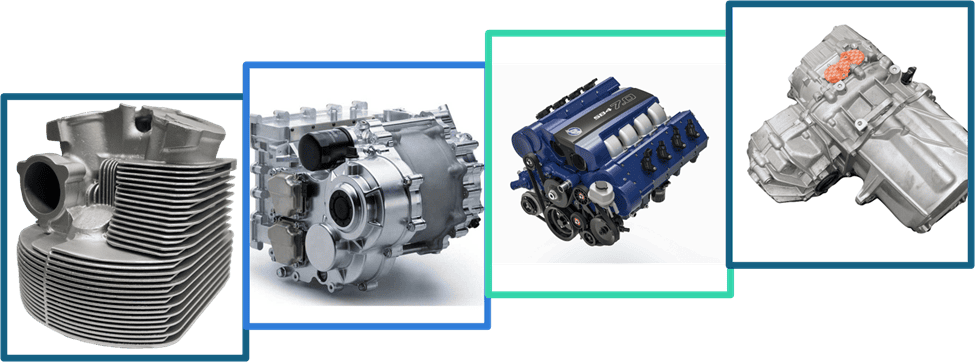

HPDC Aluminum Alloy Development for High Conductivity Applications

Al-Si cast alloys account for 80~90% of the world’s castings and HPDC specifically accounts for more than ~60% of this subset due to cost competitiveness for mass production. However, the thermal and electrical conductivity properties of Al-Si alloys are only ~50% of pure Al in the as-cast condition, which can only be increased to ~70% with resource-consuming heat treatments. Improving conductivity properties with decent strength can lead to higher performance and/or lifespan for applications such as electric vehicle powertrains, electric motor rotors, internal combustion engines, heat exchangers, etc. Alternative Al eutectic systems such as the Al-Fe, Al-Fe-Ni, Al-Ni, and Al-Ce systems offer pathways to achieve ↑ conductivity & ↑ strength for castable Al alloys. Current research focuses on establishing the significance of intertwined, hierarchical microstructural parameters that govern conductivity, strength, and castability, to provide a foundation for alloy development strategies.

To learn more about the incredible research we are doing at ACRC, click here.

POWDER PRODUCTION AND LARGE ADDITIVE MANUFACTURING AT UCI

The ACRC and metal processing team at UCI is proud to announce the establishment of comprehensive end-to-end powder processing capabilities. With the completed installation of a Warp SPEE3D Cold Spray Additive Manufacturing (CSAM) system and the recent addition of a 3D Lab ATO Lab+ and AMAZEMET rePowder ultrasonic atomization units, the UCI team can now create custom powders, process via solid-state (cold spray) or melt-based AM processes and perform any necessary post-processing on completed builds.

To support the recent installation of the ATO Lab+, 3D Lab hosted one of our Ph.D. students, Michael Ross, at their facility in Warsaw, Poland for a week-long training with their equipment suite. During this visit, Michael gained hands-on experience with ultrasonic atomization, producing powders from a variety of metals and feedstock forms, including wire and rod, as well as scrap processing via induction melting on the Induction Melting System and ATO CAST induction furnace.

We thank 3D Lab and Additive Plus for arranging the on-site visit, and Stanisław Wielowieyski for sharing his expertise and guiding Michael through his training.

RECENT PUBLICATIONS

- Cheolmin Ahn, Sean Roorda, Carl Söderhjelm, Diran Apelian, “Thermal Management of Permanent Molds“, Chapter in the Permanent Mold Handbook, Published by AFS, 2025.

Cheolmin Ahn, Carl Söderhjelm, Diran Apelian, “Evaluation of Heating Technologies for Thermal Management of Permanent Molds“, International J. of Metalcasting, 10.1007/s40962-025-01783-5

Ryan Holdsworth, Joshua Yee, Diran Apelian, Enrique Lavernia, Alan Jankowski, “Development and Use of an Automated Method for Calculated Constitutive Mechanical Property Parameter cb“, Materialia 2025, 102583, ISSN 2589-1529, https://doi.org/10.1016/j.mtla.2025.102583

Jianyue Zhang, Buwei Chen, Ravi Kuma, Qigui Wang, David Furrer, Diran Apelian, Alan A. Luo, “Role of iron content in hot tearing resistance of recycled aluminum alloy 6061“, Metallurgical and Materials Transactions B | Issue 2/2026

Qigui Wang, Jianfeng Wang, Jason Coryell, Diran Apelian, “Sustainable Pathways to Produce Aluminum Structural Castings“, J. of Sustainable Metallurgy, October 2025, https://doi.org/10.1007/s40831-025-01186-0

Sakshi Bajpai, Xin Wang, Bijun Xie, Hangman Chen, Jize Zhang, Calvin Belcher, Benjamin MacDonald, Julia Ivanisenko, Yu Zhong, Penghui Cao, Enrique J. Lavernia, Diran Apelian, “Phase decomposition in the equiatomic CoCrNi alloy“, Materialia V 44, 2025, https://doi.org/10.1016/j.mtla.2025.102554

Kentaro F. Lunn, Jovid Rakhmonov, Hsin Wang, Carl Söderhjelm, Diran Apelian, “Hierarchical microstructural parameters governing electrical and thermal conductivity in Al-based Eutectic Systems“, J. of Alloys and Compounds, August 2025, https://doi.org/10.1016/j.jallcom.2025.182055

Eunkyung Lee, Sumanth Shankar, Kentaro Lunn, Diran Apelian, “Residual Stress and Distortion in Cast Components“, in ASM Handbook on Residual Stress (2025)

- J.T. Pürstl, B. Fields P. Ziemke, N.M. della Ventura, K.M. Ainger, D. Apelian, D.S. Gianola, M.R.Begley, L. Valdevit, “Geometry assisted phase selection (GAPS): Interplay of phase heterogeneity and geometry in gyroid shell metamaterials printed with 17-4 PH stainless steel“, Advanced Engineering Materials, February 2025

- Shrivatsav Shankar, Carl Söderhjelm, Diran Apelian, “ Classification of Automotive Aluminum Scrap into Cast and Wrought Alloys via Particle Size Analysis“, Journal of Sustainable Metallurgy

Kentaro F. Lunn1, Diran Apelian, “Thermal and Electrical Conductivity of Aluminum Alloys: fundamentals, structure-property relationships, and pathways to enhance conductivity“, Journal of Materials Sci. & Eng. A (February 2025)

- Cheolmin Ahn, Carl Söderhjelm, Diran Apelian, “Enabling Technologies for Thermal Management During Permanent Mold Casting“, submitted to Journal of Material Processing Technology, December 2024.

- Calvin H. Belcher, Daisy Kamp, Sydney To, Yemao Lu, Delphine Chassaing, Torben Boll, Benjamin E. MacDonald, Elizabeth M. Y. Lee, Diran Apelian, Enrique J. Lavernia, “The origin and control of interstitial impurities in refractory complex concentrated alloys”, Journal of Alloys and Compounds

- Shankar, S., Gois, N., Molstad, E. et al. Upcycling of Low-Quality Aluminum Automotive Scrap: The DNA of Twitch. Inter Metalcast (2024).

- Mahsa Amiri, Kliah N. Soto Leytan, Diran Apelian, Daniel R. Mumm, and Lorenzo Valdevit, “Influence of Particle Size Distribution on Microstructural and Mechanical Features of Cold Sprayed Refractory Metals.” Journal of DOD Research and Engineering, 7, (2), 46-66, Jun 24

- Alan Luo, Diran Apelian, Alan Taub, “Towards Material Circularity and Manufacturing Sustainability in the Automotive Industry”, Journal of Advanced Manufacturing and Processing, 2025; 0:e70017

- Diran Apelian, Emily Molstad, Sean Kelly, Subodh Das, Barbara Reck, Alan Luo, “Sustainable Metal Production and Use in the 21st Century: Challenges and a Path Forward”, The Bridge, NAE, Summer 2024, pp 55-63.

- Mahsa Amiri, Kliah N. Soto Leytan, Diran Apelian, Daniel R. Mumm and Lorenzo Valdevit, “Controlling splat boundary network evolution towards the development of strong and ductile cold sprayed refractory metals: The role of powder characteristics”, Materials Science & Engineering A, V 902, June 2024, 146559

- Ian Geiger, Diran Apelian, Xiaoqing Pan, Penghui Cao, Jian Luo, Timothy J. Rupert, “Delayed metastable-to-equilibrium grain boundary structural transition in NbMoTaW due to chemical ordering and complexity”, Acta Materialia Volume 272, 15 June 2024, 119939

Gianmarco Sahragard-Monfared, Calvin H. Belcher, Sakshi Bajpai, Mark Wirth, Arun Devaraj, Diran Apelian, Enrique J. Lavernia, Robert O. Ritchie, Andrew M. Minor, Jeffery C. Gibeling, Cheng Zhang, and Mingwei Zhang, “Tensile Creep Behavior of the Nb45Ta25Ti15Hf15 Refractory High Entropy Alloy”, Acta Materialia.

ACRC Board Chair 2024-2026

Jason Sebastian, QuesTek Innovations LLC

“The ACRC is one of the most longstanding and successful industry/university research partnerships in the world, and it brings together researchers and industry in exciting and productive ways. Funding is leveraged to provide members precompetitive access to cutting-edge research & development project results, and access to advanced experimental facilities at UC-Irvine and OSU. Members can select and steer the R&D projects through their active participation in project steering committees and at the ACRC semi-annual in-person meetings. The consortium provides incomparable networking opportunities with top-notch university researchers at UC-Irvine and OSU, and with decision-making executives and managers at high-tech, materials-centric industry member companies. As ACRC Board Chairman, I look forward to helping the ACRC to continue and expand upon its successes in the years to come.”