Funded by ACRC Consortium

Funded by Federal Agencies

Overview

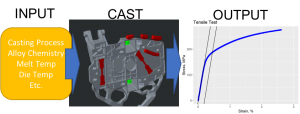

This project will reduce costs and lead times for DLA / DoD procurements through improvements in the additive manufacturing of tooling for metal mold process parts. Develop and qualify additive manufacturing design guidelines, processes, and materials for fabrication of rapid tooling, including tooling with conformal cooling lines.

Researchers: C. Soderhjelm, D. Apelian

Category: Funded by Federal Agencies

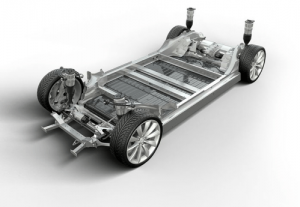

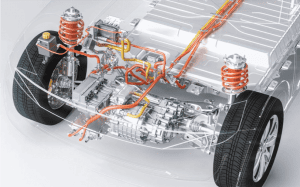

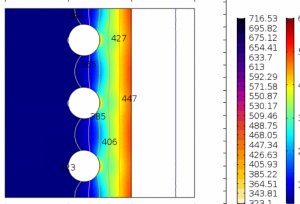

Increasing demand of aluminum die castings in structural and other applications are increasing due to their great performance to cost ratio. However, for the technology to stay relevant it has to keep up with the increasing demands, financial and technological, of the manufactured components. Superior properties and cycle times can be achieved by improving the thermal management during die casting of aluminum alloys. Heat extraction from the casting is key to achieve optimized castings at a higher cycle rate. Conformal cooling channels within the dies and its tools has the potential to create uniform and more efficient heat extraction. However, the complex geometries of that go hand in hand with conformal cooling channels are expensive and, in some cases, impossible to manufacture.

One of the great advantages of many additive manufacturing processes is the design freedom it offers. Building components from the bottom up, layer by layer, allows for the creation of complex shapes which would be impossible to make with traditional manufacturing methods. The flexibility of the additive manufacturing processes allows for possible reductions in both cost and lead times for tooling for the die casting industry.

A total of five die casting tools, such as cores and inserts, will be identified to be used for the qualification of additive manufacturing processes and materials. Successful results are considered when the lead time for manufacturing the tools is reduced from weeks to days and the tool life is comparable to the traditional H13 machined tools. From the work described below a set of guidelines for designing tooling with conformal cooling lines will be established.

Overview

Ultimately, this effort will reduce logistical issues by enabling the reuse of waste iron, prove the feasibility of field-capable manufacturing, reduce equipment down-time, and increase operational readiness.

Category: Funded by Federal Agencies

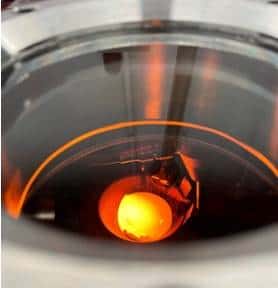

There is a need to improve the material sustainability of the warfighter. Currently, forward operating bases (FOB) produce an abundant amount of ferrous (iron) waste, which cannot be removed due to security reasons and local infrastructure constraints. However, an agile manufacturing process enables the reuse of scrap metal to produce needed parts for the warfighter.

Three manufacturing stages are addressed:

(1) quality control of the feedstock scrap material

(2) a stereolithography (SLA) enabled investment casting (IC) process, and

(3) post-process heat treating.

Overview

Researchers: C. Crook, L. Valdevit, D. Mumm, D. Apelian

Category: Funded by Federal Agencies

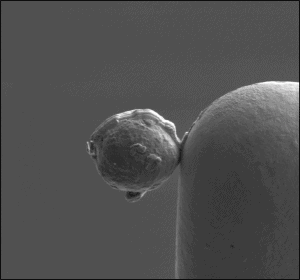

Cold spray is promising technology for coatings, additive manufacturing, and repair of worn and corroded parts. Among its advantages are low temperatures, minimal oxidation, preservation of the powder feedstock’s microstructure, and a broad assortment of sprayable materials. However, the process is incredibly sensitive to the powder feedstock quality and it is not yet well understood how the composition and thickness of the powder’s passivation layer influences the critical velocity of powder particles. There is some indication that the formation of hydroxide and oxyhydroxide phases from absorbed water in the air contribute to a more ductile passivation layer which does not fracture during impact resulting in weaker deposits. Comprehensive studies of these effects in complex engineered alloys, such as widely used Al6061, will provide a foundation for improvements to powder storage and treatment to better combat adverse effects on the cold spray process.

Overview

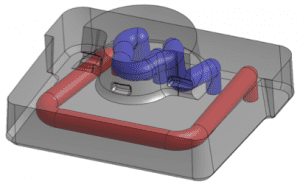

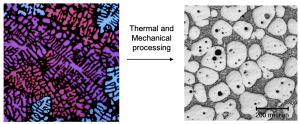

The high viscosity of the material keeps it from flowing after being extruded, allowing it to keep the shape laid out by the nozzle.

Researchers: R. Eberheim, C. Soderhjelm, D. Apelian

Category: Funded by Federal Agencies

Additive manufacturing has enjoyed explosive growth in recent decades thanks to the ability to reduce production times, reduce raw material consumption, and generate new geometries. Currently additive manufacturing with metals is largely dependent on powders which make the process slower, more expensive, and more hazardous than direct deposition based techniques, more commonly using for plastic additive manufacturing. This research aims to develop a new technique for metal additive manufacturing analogous to fused filament fabrication (FFF) for plastic printers. This is made possible by using semi-solid metals as the printing material. Semi-solid metals consist of an alloy which has both solid and liquid phases enabling the material to exhibit viscoelastic behavior so that it can be extruded through a nozzle into layers.

Reference:

- Chen, L.Thornley, H. Coe, S. Tonneslan, E. Duoess, R. Hunt, M. Wight, D. Apelian, A. Pascall, J. Kuntz, C. Spadaccini, ”Direct Metal Writing: Controlling the Rheology through Microstructure”, Appl. Phys. Lett. 110, 094104 (2017)

Funded by Industry

Overview

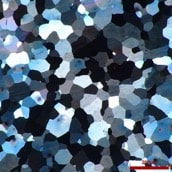

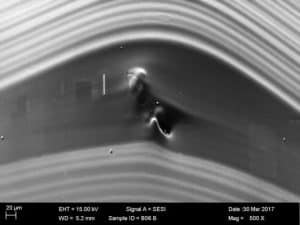

The twin defect region is examined by structural, chemical and electrical characterization in heavily doped silicon crystals, which twinned during growth. Twin formation theories are examined and tested against the new measurements.

Researchers: J. Kearns, D. Apelian

Category: Funded by Federal Agencies

Advanced, low voltage power control electronics are needed to enable low power consumption computers, telecommunications and automotive devices. Lower voltage power electronics are made from dislocation-free silicon heavily doped with arsenic or antimony to provide extremely small electrical resistivity. As crystal resistivities have been lowered to attempt to achieve lower power losses, twinning of the crystal has unexpectedly occurred during growth, so that the crystal no longer possesses the required crystallographic orientation for device function. The purpose of this project is to determine the mechanism of twin formation, so that crystal growth process conditions can be designed to eliminate this defect and allow lower resistivity crystals to be grown reliably.

Overview

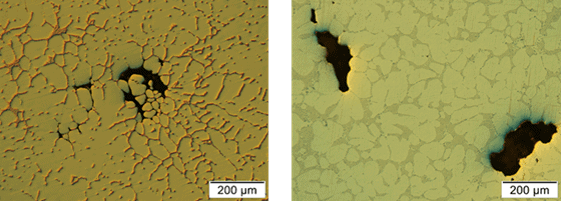

The aim of this project is to investigate those phenomena in Al-alloys and establish a deeper understanding of the solidification dynamics; this will enable us to better predict the location of defects in castings.

Researchers: A. Jean-Philippe, H. Brody (UCONN), D. Apelian

Category: Funded by Industry